Power Plant Projects

Automation of DM & Softening Plant for Indocan Engineering System Ltd, Pune

GEIP Series 90- 30 with 400 DI/Dos and 32 AI were used for controlling the complete operation of DM & Softening plant. The control and sequential operation of whole plant was performed using GEIP SCADA software. The PC was interfaced with PLC through Ethernet network. SCADA software included process control and monito ring through softket and alarm management. System was capable of generating reports/logs like Event activate. Time activated, and operator demand log summaries. System was capable of real time and historical trending. The PLC was provided with bump less Hot Standby Redundancy (HBR). At the modes i.e. Pre Services, Service & Regeneration of DM as well as Softening was controlled through PLC. The PLC system was capable of operating in automatic, semiautomatic, manual control with commands from keyboard. Analog variables such as pH, conductivity, flow, level a ll the tanks were interfaced with PLC. PLC was provided with DCS connectivity to access a PLC data.

Hydel Power generation project (2X5500) KW

Customer

Kirloskar Brother ltd Pune

End User

Ronghli kola hydel power generation station

Location

Sikkim

System consist of PLC Ge-IP Make with SCADA SOFTWARE ON PC Control system was designed to perform

- To control turbine automatically.

- With the help of SCADA Software, such as on /off control can be set and monitor the

Alarms and interlock etc, data logging facility on PC - Digital input-64, digital output 36

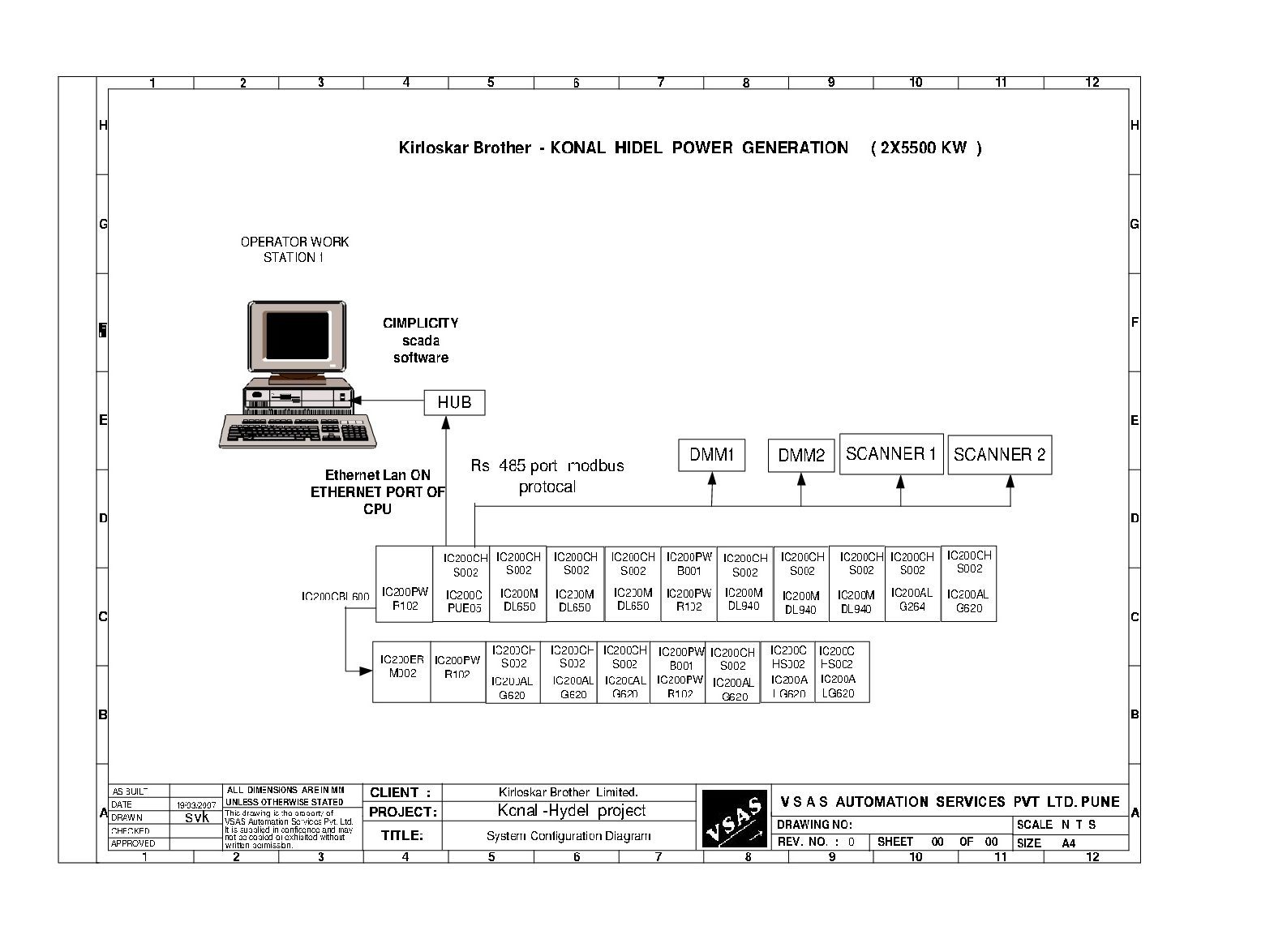

( 2X5500 ) KW HYDRO POWER PLANT AT KONAL

Customer

Kirloskar brother ltd pune

End User

Govt of Maharashtra irrigation dept

Contractor

Mahalaxmi Vidyut pvt ltd pune

Location

KONAL

System consist of PLC Ge-IP Make with SCADA SOFTWARE ON PC Control system was designed to perform

- To control turbine automatically.

- With the help of SCADA Software, such as on /off control can be set and monitor the Alarms and interlock, temperature and power monitoring etc, data logging facility on PC

- Digital input-64, digital output 36

- Power meter on modbus and temperature scanner on modbus communication are Involved in this project for data monitoring and control action further.

Compressor Automation

Customer

Kirloskar Pneumatic ltd pune

End User

West Bangal Power development corporation

Consultant

BHEL

Location

West Bangal

Application Requirement

To control the Four no. of compressor from SCADA And locally from Control desk

System consist of PLC Ge-IP Make with SCADA SOFTWARE ON PC Control system was designed to perform

- To control the Compressor qty 4 no Along with Air drying Plant 4 no Combine control from plc .

- With the help of SCADA , parameters such as on /off control can be set and monitor the Alarms and pressure, flow etc for the compressed air .

- ADP plant is controlled on modbus communication.

- Total I/o count – Digital Input – 196, digital output- 160, Analog input -64 RTD -24

About Vsas Automation

Since its establishment in 1994 VSAS has travelled a long way in the field of automation. Over a period of time we have groomed ourselves into a complete automation solution provider. With the inclusion of PLC, VFD, Servo, HMI, SCADA and electrical actuators based services you get everything under one roof. Today VSAS is one stop shop for tailor-made process and machine tool automation solutions.

Head Office

Phone: +91-20 25442302/4/5

Quick Links

Solutions

- Vegetable Oil

- Water

- Material Handling

- Automotive

- Process

- Packaging